Metallurgy

-

With the rapid development of industrial automation process control theory and computer, the reliability, complexity, function perfection, system maintainability, man-machine interface friendliness, data analysis, management and other aspects of industrial automation process control system are put forward higher and higher requirements. The simple PLC system can not meet the requirements of today's automatic process control system Unified design standards and requirements.

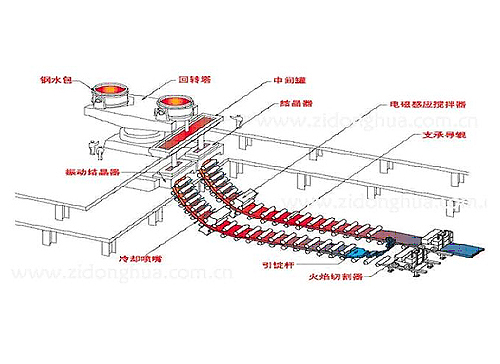

The production process of continuous casting is that the qualified molten steel after converter smelting and ladle refining is hoisted onto the ladle turret of continuous casting machine. After pouring, it is poured into the tundish and divided into the mould. The original shell is formed by forced cooling of the mould. Under the tension of the straightener, the slab with liquid core is gradually formed in the secondary cooling chamber and straightened to the required size.

The solution of three electricity integration system for continuous caster provided by our company is an integrated system integrating PLC, DCS and computer functions. PLC is specially used to process instrument detection signals and automatically control secondary cooling water distribution. The computer monitors all kinds of instrument signals, displays dynamic pictures and process information, completes statistical reports, participates in centralized display and alarm of fault information, and carries out man-machine dialogue. The system can realize timely control of caster production.